Debris Catchers That Fit Your Needs

Protect your wellhead equipment with debris catchers that are engineered to make your job site safer and more efficient.

Turn-key – Field ready and assembled.

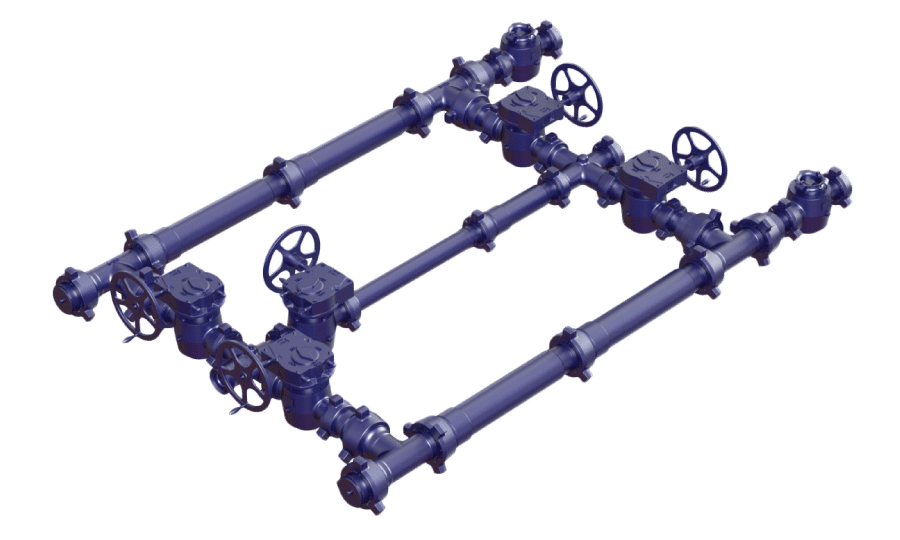

Custom & Stock Manifolds

Our stock debris catchers are designed to fit any manufacturer’s parts for smooth integration into existing programs, and we can custom-fabricate a configuration that fits your site.

Easy Installation & Maintenance

Engineered blow-down style and multiple barrels allow for continuous screening without shutting in the well for cleaning.

| SOUR SERVICE PART NUMBER | STD SERVICE PART NUMBER | DESCRIPTION | Sour Pressure Rating | Std Pressure Rating | FRAME SKIDS | CONTAINMENT SKIDS |

| MANDC0400 | SINGLE BARREL DEBRIS CATCHER – 4″ FIG 1502 X 2″ FIG 1502 | 10000psi | SKIDF-007 | SKIDC-011 | ||

| MANDC0401 | MANDC0453 | DUAL BARREL DEBRIS CATCHER – 4″ FIG 1502 X 2″ FIG 1502 | 10000psi | SKIDF-025 | SKIDC-012 | |

| MANDC0402 | SINGLE BARREL DEBRIS CATCHER – 4″ FIG 1502 X 3″ FIG 1502 | 10000psi | SKIDF-008 | SKIDC-008 | ||

| MANDC0403 | DUAL BARREL DEBRIS CATCHER – 4″ FIG 1502 X 3″ FIG 1502 | 10000psi | SKIDF-005 | SKIDC-013 | ||

| MANDC0404 | MANDC0405 | DUAL BARREL DEBRIS CATCHER – 4″ FIG 1502 X 3″ FIG 1502 | 10000psi | 15000psi | SKIDF-003 | SKIDC-004 |

| MANDC0406 | VERTICAL DEBRIS CATCHER – 3″ FIG 1502 | 10000psi | ||||

| MANDC0407 | DUAL BARREL DEBRIS CATCHER – 4″ FIG 1502 X 3″ FIG 1502 | 10000psi | SKIDF-026 | SKIDC-014 | ||

| MANDC0408 | DEBRIS CATCHER – 4″ 10K W/ 3″ FIG 1502 OUTLET | 10000psi | ||||

| MANDC0409 | MANDC0410 | DUAL BARREL DEBRIS CATCHER – 4″ FIG 1502 X 3″ FIG 1502 | 10000psi | 15000psi | SKIDF-003 | SKIDC-004 |

| MANDC0411 | DUAL BARREL DUAL BARRIER DEBRIS CATCHER – 4″ FIG 1502 X 3″ FIG 1502 | 10000psi | SKIDF-027 | SKIDC-003 | ||

| MANDC0412 | DUAL BARREL DUAL BARRIER DEBRIS CATCHER – 4″ FIG 1502 X 3″ FIG 1502 W/ 4 HYD ACT VALVES | 10000psi | SKIDF-027 | SKIDC-003 | ||

| MANDC0413 | DUAL VERTICAL DEBRIS CATCHER DUAL BARRIER – 3″ FIG 1502 | 10000psi | SKIDDC-002 | |||

| MANDC0414 | DUAL BARREL DEBRIS CATCHER – 4″ FIG 1502 X 3″ FIG 1502 | 10000psi | SKIDF-028 | SKIDC-005 | ||

| MANDC0415 | DUAL BARREL DEBRIS CATCHER – 4″ FIG 1502 X 3″ FIG 1502 | 15000psi | ||||

| MANDC0416 | DUAL BARREL DUAL BARRIER DEBRIS CATCHER – 4″ FIG 1502 X 2″ FIG 1502 | 10000psi | SKIDF-029 | SKIDC-015 | ||

| MANDC0417 | DUAL BARREL DUAL BARRIER DEBRIS CATCHER – 4″ FIG 1502 X 2″ FIG 1502 | 15000psi | SKIDF-030 | SKIDC-016 | ||

| MANDC0418 | HORIZONTAL DEBRIS CATCHER – 3″ FIG 1502 | 10000psi | SKIDF-001 | SKIDC-009 | ||

| MANDC0419 | MANDC0420 | DUAL BARRIER DUAL VERTICAL DEBRIS CATCHER – 3″ x 2″ FIG 1502 | 10000psi | 15000psi | SKIDDC-004 | |

| MANDC0421 | MANDC0422 | HORIZONTAL DEBRIS CATCHER – 3″ x 2″ FIG 1502 | 10000psi | 15000psi | SKIDF-002 | SKIDC-010 |

| MANDC0423 | MANDC0424 | SINGLE BARRIER DUAL VERTICAL DEBRIS CATCHER – 3″ x 2″ | 10000psi | 15000psi | ||

| MANDC0425 | MANDC0426 | HORIZONTAL DEBRIS CATCHER – 3″ FIG 1502 | 10000psi | 15000psi | SKIDF-031 | SKIDC-017 |

| MANDC0427 | MANDC0428 | HORIZONTAL DEBRIS CATCHER – 3″ FIG 1502 (3″ Outlet) | 10000psi | 15000psi | ||

| MANDC0429 | DUAL BARREL DEBRIS CATCHER – 4″ FIG 1502 INLET X 3″ FIG 1502 | 10000psi | SKIDF-032 | SKIDC-018 | ||

| MANDC0430 | MANDC0431 | QUAD BARREL DEBRIS CATCHER – 3″ FIG 1502 | 10000psi | 15000psi | ||

| MANDC0432 | MANDC0433 | DUAL BARREL DUAL BARRIER DEBRIS CATCHER – 4″ FIG 1502 X 3″ FIG 1502 X 2″ FIG 1502 | 10000psi | 15000psi | SKIDF-024 | SKIDC-019 |

| MANDC0434 | DUAL VERTICAL DEBRIS CATCHER DUAL BARRIER – 3″ FIG 1502 – LOW TORQUE VALVES | 10000psi | ||||

| MANDC0435 | MANDC0436 | HORIZONTAL DUAL BARRIER DEBRIS CATCHER – 3in x 2in FIG 1502 | 10000psi | 15000psi | SKIDF-041 | SKIDC-020 |

| MANDC0437 | MANDC0438 | DUAL BARREL DUAL BARRIER DEBRIS CATCHER – 4″ FIG 1502 X 3″ FIG 1502 | 10000psi | 15000psi | ||

| MANDC0441 | MANDC0442 | HORIZONTAL DUAL BARRIER DEBRIS CATCHER – 3″ FIG 1502 (3″ OUTLET) | 10000psi | 15000psi | SKIDF-043 | SKIDC-022 |

| MANDC0443 | MANDC0444 | DUAL BARREL DEBRIS CATCHER – 4″ FIG 1502 X 3″ FIG 1502 BOWEN CONNECTIONS & NO GUT LINE | 10000psi | 15000psi | ||

| MANDC0445 | MANDC0446 | SINGLE BARREL DEBRIS CATCHER – 4″ FIG 1502 X 3″ FIG 1502 X 2″ FIG 1502 | 10000psi | 15000psi | ||

| MANDC0447 | MANDC0448 | HORIZONTAL DEBRIS CATCHER – 3″ x 2″(LT) FIG 1502 | 10000psi | 15000psi | ||

| MANDC0449 | MANDC0450 | DUAL BARRIER DUAL VERTICAL DEBRIS CATCHER – 3″ FIG 1502 | 10000psi | 15000psi | ||

| MANDC0451 | DUAL VERTICAL DEBRIS CATCHER SINGLE BARRIER – 3″ FIG 1502 | 10000psi | SKIDDC-006 |

Personalized Service

- Phone support & troubleshooting 24/7

- New and recertified products delivered quickly

- Testing and recertification on any manufacturer’s parts on or off site

- Certification and asset tracking with RDI’s Iron Management System

Not Finding What You’re Looking For?

RDI manufactures iron products to the highest quality industry standard. Our manufacturing experts with a team of engineers provide custom products to solve problems that pre-fabricated parts might not solve. Contact us today.